Coating

What is Tedlar®?

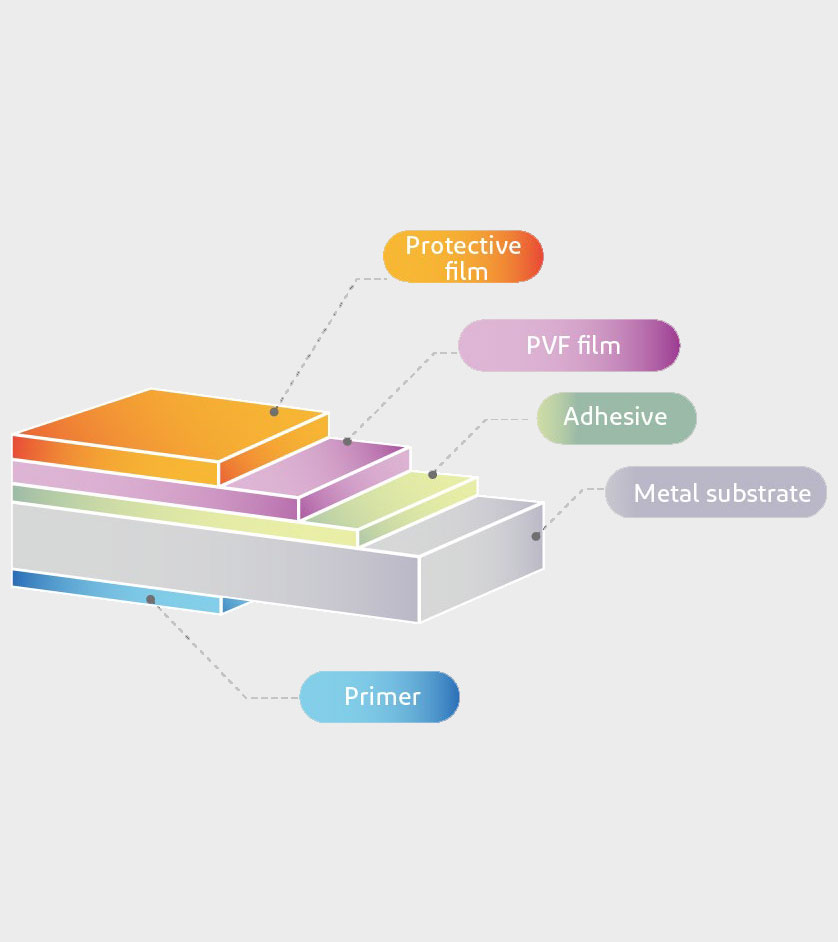

Tedlar®is a DuPont registered trademark for a highly versatile polyvinyl fluoride (PVF) film that provides a long-lasting finish to a wide variety of surfaces exposed to harsh environments.

DuPont invented polyvinyl fluoride (PVF) polymer in the 1940s, and by the 1950s began developing products based on the material.

In 1961, DuPont registered the Tedlar®brand name in the US and construction started on its first production facilityin Buffalo, NY. Completed a major capacity expansionin 2012.

More than fifty years later, Tedlar®film is recognized as the high-performance standard for surface protection, with proven durability in harsh operating environments.

Proven applications:

Aerospace & Transportation

Building & Construction

Composite Release

Signage

Industrial

Photovoltaics

Why Do Customers Use Tedlar®PVF Film?

Tedlar®PVF film has been used in numerous building product applications for over 50 years. It provides cost-effective long lasting aesthetic protection for architectural applications, even in extreme outdoor environments. No coastal restrictions. It can preserve and extend a building’s appearance and lifetime by preventing building facades from fading, cracking or corroding. Tedlar®PVF films are stain resistance and easy to clean that to reduce maintenance costs to provide lower total life cycle cost of buildings.

Excellent weatherability

Corrosion, chemical, stain/graffiti resistant

Can withstand the harshest chemicals without damage

UV resistant maintaining colors for years

Available in several colors inspired by nature

Long-term stability with low signs or fading, chalking or visible cracking

Chemically inert surface to protect against harsh solvents and pollution

Easy to clean stains and graffiti for reduced maintenance cost

Case Study

Hilton Head Island Oceanfront Resort Roof Project

Tedlar® PVF film was recently selected as a protective roofing material for the Sea Crest Condos in Hilton Head, South Carolina. It includes a 6-story building constructed approximately 20 years ago that sits directly on the beach of the Atlantic Ocean. The existing steel roof panels and framing of the building were severely corroded and the owner was looking for a long-term solution to withstand an extremely corrosive environment.

Construction Metal Products (CMP), a leading panel producer in the Carolinas, was selected to facilitate the renovation project and recommend suitable materials. They were presented with two options. The first being to install a standard coastal paint finish on an aluminum base metal and have the burden and expense of scheduling, executing, and documenting yearly maintenance to maintain the paint finish warranty. The second option was to install Tedlar® on an aluminum base metal with no maintenance requirement to maintain the finish warranty.

Aluminum panels laminated with Tedlar® from our partner Metal Alliance were ultimately chosen for their excellent durability by the coast, even as close as 1,500 feet from the ocean. Additionally, Tedlar’s® excellent flexibility allowed it to bend to tight edges on the roofing panels without compromising film integrity or adhesion, thus assuring the roof is protected and looks brand new for decades. Installers commented that Tedlar® was much more durable and hardier during installation than a standard PVDF/Kynar® paint finish. They also noted the ease of installation of the panels and the excellent finished look of the roof.

This project was installed by RPI Roofing with panels supplied by Construction Metal Products, from coils provided by Metal Alliance. Metal Alliance Tedlar® products are available with up to 50-year warranties and no coastal restrictions, offeringrevolutionary protection to the metal building panel market.